LensCars has its finger on the Pulse

Belgian bus repair and service center selects Graco’s innovative fluid management system

With the installation of the Pulse™ Fluid Management system, vehicle service shops can easily monitor precisely what type of fluid is being used, where it’s going, when it’s dispensed and who’s performing the work. It thus enables companies to simplify their operations, capture previously lost or unassigned costs, and uncover hidden profits. One company to recently adopt Graco’s Pulse solution is LensCars in Belgium.

ONE-STOP SHOP

LensCars is a repair and service center specializing in buses. This one-stop shop performs mechanical, electro-pneumatic, automation, multimedia, bodywork and paintwork jobs – all in one facility. Focusing on providing impeccable service to its customers, LensCars is now the central repair and service center in Wallonia for bus brands IVECO, VDL and Solaris; whether the buses are diesel, hybrid or electric.

The company was established by brothers Julien and Francis Potty in 2002. It started in a rented factory of 2,500 m² in the Belgian town of Lens-Saint-Rémy, 30 km east of Liège. Initial operations were focused on agricultural and civil engineering machinery. Business soon took off and in 2003, a contract with IRISBUS led to an increasing focus on buses. This paid off with a contract for the technical upgrading of the Renault buses of the Regional Walloon Transport Company.

TIME TO EXPAND

By 2004 it was already time to expand; the first designs for a larger and more modern facility were sketched solely to meet the maintenance requirements of buses. The new industrial zone in nearby Villers-le-Bouillet was chosen as ideal location. Construction work started in 2007 and the 12,000 m² facility opened in April 2008. It was marked by a spare parts and service contract with IVECO Bus.

Since then, LensCars has continued to invest. A new workshop was constructed in 2015 to separate the technical/mechanical work from the bodywork business. In 2016 a new roller bank was purchased for the approval of limiters and tachographs. The following year a Kardex automatic warehouse was installed. Soon to be opened is a purpose-built automatic Coach-Wash with water recycling.

LensCars is now managed by Samuel Potty who has taken over from his father and uncle. Currently the company has a workforce of 22. Every morning sees up to six buses entering through the front gates. Some will stay just for the day before being sent back on their rounds in perfect condition once more. Others might stay for up to two months if major work is required.

The Pulse Pro system was quickly installed in one day by a single Graco technician. All LensCars personnel were impressed at how simple the system was to use; no training was necessary. “It was very much plug-and-play!” says Potty.

AUTOMATING FLUID DISPENSING

The company’s most recent acquisition is Graco’s Pulse™ Fluid Management system that will enable LensCars track their fluid dispenses. Composed of few devices interconnected on a wireless device network, Pulse authorizes fluid dispensing for LensCars, monitors the amount of fluid dispensed and measures current inventory levels.

At LensCars, Pulse operates on a low powered, wireless device network that interconnects the handheld smart meters, pump controllers and tank level monitors. Pulse creates and manages this network through the Pulse Hub, which is a single board computer than runs a custom, Linux-based operating system. This hardware forms the lower powered device network, runs the Pulse application that controls the Pulse devices and hosts a webpage in the LensCars main office for user interaction with the system. To allow end users to easily access the Hub from their own PCs and devices, the Hub is connected to the local LAN.

“Previously we were dispensing fluids such as engine oil and coolants manually,” explains Samuel Potty. “Sometimes technicians would forget to record the dispense of, for example, ten liters of engine oil. With the quality and therefore the price of oil ever increasing, if that happens repeatedly it’s a significant loss of income for us. Pulse automatically monitors and records every single liter we use. No discrepancies means no lost income.”

The Pulse system was quickly installed in one day by a single Graco technician. All LensCars personnel were impressed at how simple the system was to use; no training was necessary. “It was very much plug-and-play!” says Potty. As to the financial savings, Potty believes they will be significant but he will have a better view after the system has been in operation for six months.

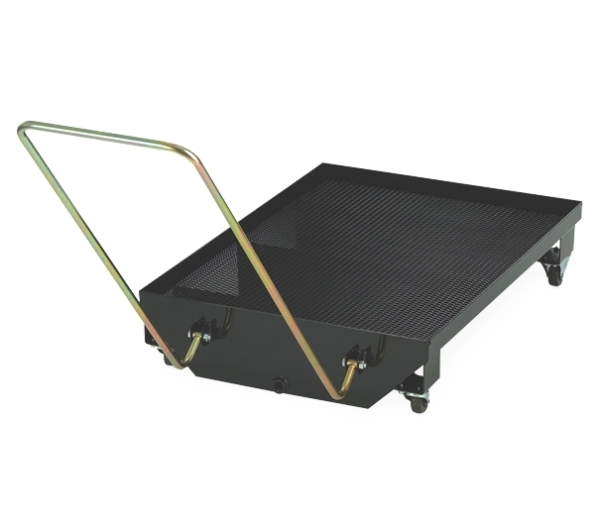

UNIQUE MOBILE DISPENSE CARTS

Another benefit of the system is that each of the eight engine oils and two coolants used in the facility has their own gun which is mounted on individual mobile roll-around dispense carts. They enable each LensCars technician to easily maneuver the oil drum right up to the bus engine, which removes the need for long and potentially dangerous hoses trailing over the shopfloor.

The Pulse system is wholly scalable. The only components necessary to monitor exactly what and how much fluid the technicians are dispensing are the Pulse Hub and the Pulse Dispense Meter. Later, other Pulse components such as the Pulse Tank Level Monitor can be easily added to the system.

LensCars decided to go with the Pulse Tank Level Monitor right from the start. “We find this a very useful additional component as it automates inventory management,” remarks Potty. “This is because the main Pulse screen in the main office visually shows the levels of fluid in each drum. I can therefore easily see when it’s time to order a new drum of oil or coolant. Even better, the Pulse system also sends an email notification when the amount of oil in a drum is dropping below a specified level. It’s then a simple matter of sending an email to the appropriate fluid supplier.”

Another optional and useful component is the Pulse Pump Air Controller, which shuts off air to the pump automatically when not in use, to prevent broken lines or draining tanks from leaking fluid all over the shop floor. A variety of extenders can also be added to extend the reach of Pulse throughout a facility.

Tank level automatic email notification can also be programmed to be sent to the oil supplier directly. Then LensCar only need to confirm supply order.

PULSE BENEFITS IN A NUTSHELL

No matter the size of the installation, Pulse™ Fluid Management enables valuable insights to be gained into bulk fluid management:

- Transparency: Automatically monitor every drop, every time to minimize shrinkage, rounding and invoice discrepancies.

- Accountability: Track issues to the source via advanced technology, including automated alerts and customizable reports.

- Integration: Capture data, integrate it with popular DMS’s and share it with other stakeholders quickly to improve scheduling, inventory, procurement, pricing and more.

- Portability: Easily pair with mobile dispense units and drums to reduce extra steps and hassles for technicians.

- Scalability: Add Pulse into any environment quickly, even retrofit applications or multiple buildings within the same facility, and avoid excessive installation costs and delays.

- Accurate billing: Automatically assign every ounce of fluid directly to a work order to simplify billing and maximize profit margins.

- Simplicity: Avoid surprises, interruptions and delays. Fluids are tracked and recorded instantly and automatically, so technicians can spend more time in the service bay – serving more customers.

TECHNICAL SPECIFICATIONS

Pulse Fluid Management is compatible with petroleum and synthetic based oils (including automatic transmission fluid and gear lube), anti-freeze and windshield wash solvent. It is certified for interfacing with common dealer management software providers such as Reynolds & Reynolds®, CDK Global®, Procede Software, Dealertrack, PBS Systems and X-Power. Software access is via all major web browsers. It operates on 100-240 VAC line voltage for wired products and AA alkaline batteries for battery powered devices.

MORE INFORMATION

If you have questions about Pulse™ Fluid Management or require more information on the system or components, fill out the contact form below or visit the Graco webpage.

Pulse Pro - Fluid Management

Graco's Pulse® Pro Fluid Management system is an innovative wireless fluid management system for vehicle and fleet service. The Pulse Pro system provides forward-thinking service operations with the insight, control and analytics needed to simplify decisions and drive profitability in the age of the...

Pulse FC - Fluid Control

With Pulse® FC, dispense only precise volumes to create efficiencies for your entire vehicle or fleet service operation. Monitor how much fluid you’re using. Choose the amount of fluid each technician can dispense. Maintain accurate inventory. Streamline processes to improve productivity and uncover...

Related Articles

Check your Pulse

Take this quick quiz to find out what fluid inventory control or management system is right for you — and discover how it can greatly improve your operation’s productivity and efficiency.

Related Articles

The Importance of Waste Oil Management

Discover best practices for managing used oil.

Fluid Management Helps Beverly Hills

Matrix Fluid Management streamlines operations for fleet service center.

Converting Existing Service Facilities to Fluid Management

Identifying misconceptions and planning the conversion for a fluid management system.