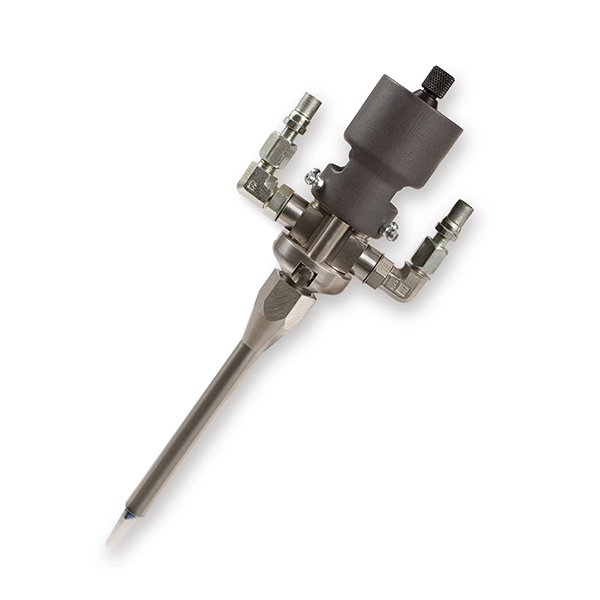

Two Component Mixing Dispense Valve

Static mixing dispense (MD) valves handle a range of flow rates and viscosities. Accurately mix and dispense two component (2K) sealants and adhesives to efficiently meet assembly application demands.

IMPROVE PRODUCTIVITY

Minimize maintenance downtime and costs, while maximizing uptime. Automatic and manual mixing dispense valves meet the challenges of plural component materials like these:

- Acrylics

- Epoxies

- Polysulfides

- Silicones

- Thermal interface materials (TIMs)

- Urethanes and polyurethanes

Browse Two Component (2K) Mixing Dispense (MD) Valves

Choose Elite construction for applications of highly abrasive thermal interface materials (TIMs), silicones, urethanes, and epoxies. When your system configuration includes pumps and valves with Elite construction, you can expect to…

- dispense at least 50,000 gallons (200,000 liters) before noticing any wear on pump pistons and cylinders*

- get at least 10 times more equipment life, compared to standard systems*

How do we know? Read the research.

* Results may vary. Variables affecting component life include, but are not limited to, material chemistry/fillers, flow rate, cycle rate, maintenance diligence, and system pressure.

Documents & Videos

Articles & Case Studies

Extreme Material Abrasiveness? Problem Solved with Elite

Some thermal interface materials (TIMs) are so abrasive, it’s like pumping diamond dust or liquid sandpaper. Explore why and how we developed Elite, the longest-lasting pump construction for abrasive material dispense.

Improving Quality & Efficiency When Using Adhesives

Discover how proper mixing and accurate, on-ratio dispensing of adhesive components enhance bonding and sealing in insulating glass and curtain wall production. Explore improved mixing technology and high-pressure, high-flow proportioners for efficient adhesive application.

Potting Solar Panel Junction Boxes

Solar panel manufacturer decreases costs, improves manufacturing efficiency, and meets panel quality expectations with advanced meter, mix and dispense.

Real-time Ratio Monitoring Critical for Adhesives in the Glass Industry

Discover the importance of real-time ratio monitoring in the glass industry. Learn how accurate mixing and on-ratio dispensing of adhesive components impact the success of bonding and sealing processes for insulated glass and curtain wall applications.

Silicone Sealant for Solar Frame Attachment

Discover how a solar panel manufacturer improved bead profile consistency for solar frames using Graco automated silicone dispensing solutions.

Videos

Free Service Webinar

MD2 Valve Seat Rebuild

In 30 minutes or less, review the difference between a soft seat and a hard seat valve. You'll also learn how to properly rebuild the wetted section of the valve.