Automotive Plant ‘Sets and Forgets’ Surge Suppressors

Maintenance-free pump accessory dampens paint circulation line pulsation.

CUSTOMER: Automotive Original Equipment Manufacturer (OEM)

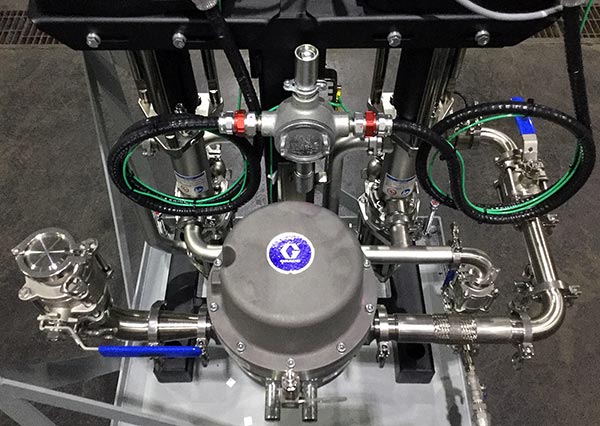

GRACO EQUIPMENT: Active Surge Suppressor

CHALLENGE: A large automotive plant was replacing a number of obsolete centrifugal pumps with electric pumps. Concerned that pressure fluctuations from paint circulation lines might affect other parts of the factory, the plant’s district manager wanted to be sure the new pumps came with surge suppressors.

Most surge suppressors require extra equipment and time from already busy maintenance crews.

- For initial setup, they need high-pressure charge air that’s not conveniently available and usually provided by nitrogen cylinders.

- For regular maintenance, a crewmember needs to carry the air cylinders around while checking the air pressure in each suppressor and re-charging as needed.

Regular maintenance is often forgotten. Leaving surge suppressors unattended results in reduced pulsation dampening due to inadequate air pressure. Paint leaking due to a ruptured suppressor diaphragm is another concern.

SOLUTION: Knowing they needed a maintenance-free solution, plant engineers decided to try Graco’s newest paint kitchen accessory: the active surge suppressor.

- For initial setup, they’d simply connect the active surge suppressor to the compressed air that’s already available in the plant.

- For regular maintenance, they wouldn’t need to do anything. The active surge suppressor automatically adjusts air chamber pressure to stay on target.

A booster piston inside the active surge suppressor separates the fluid chamber and the air chamber. This keeps paint from getting into the air chamber and leaking out, if the diaphragm ruptures.

RESULTS: The industrial paint kitchen equipment upgrade paired 11 active surge suppressors with 11 E-Flo DC electric pumps. The setup continues to work properly without technical issues.

After connecting 11 active surge suppressors to compressed air, maintenance staff has not needed to pay any attention to the new equipment. They could “set it and forget it.”

In addition to maintenance-free pulsation dampening, the manufacturer realized a $300,000 annual savings due to the more efficient electric pumps.

Paint Shop

With the automotive industry demanding higher performance, paint shop success depends on equipment that fits changing needs.

Related Articles

Passive vs. Active Surge Suppressors

Also called “surge tanks,” surge suppressors remove pressure pulsations from paint lines. Video explains the difference between passive and active surge tanks.

Finishing Solutions for Automotive Components

Get the flexibility to apply primers, base coats, and top coats with a single system.

5 Ways to Reduce Unplanned Downtime

Looking for ways to stop unplanned downtime? Follow our simple tips, and downtime should not be a problem.